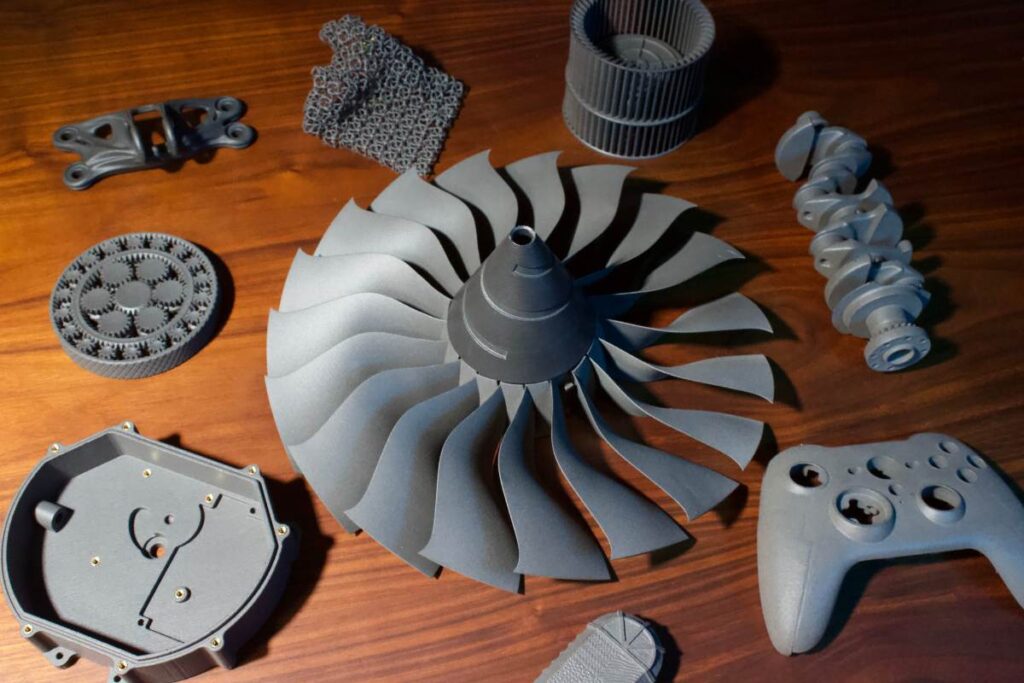

In recent years, the powder bed fusion (PBF) 3D printing has established itself as one of the most revolutionary technologies in additive manufacturing. In contrast to more limited 3D printing methods, PBF offers unprecedented design freedom, allows produce functional parts with geometries impossible to produce by injection moulding or machining, It has opened up new horizons for sectors such as the automotive, aeronautical, medical and industrial sectors.

At Additium 3D we see it every day: where once there were limitations, today there are real opportunities to manufacture faster, more accurately and without moulds.

What is powder bed fusion (PBF)?

The powder bed fusion (from English Powder Bed Fusion, PBF) is a technology of additive manufacturing in which a very thin layer of powdered material (usually polymers, metals or composites) is deposited on a printing platform. Then, a laser or thermal energy source selectively melts the powder in the areas corresponding to the 3D design.

Layer by layer, the process is repeated until a solid, precise and fully functional part is created.

Once printing is complete, the unfused powder is removed, which can be reused in future prints, making the process efficient and sustainable.

What is powder bed fusion 3D printing?

When we talk about powder bed fusion 3D printing, The term "laser energy" refers to a set of technologies that share the same principle: using heat or laser energy to melt fine dust particles and form a solid piece.

Among the best known are SLS (Selective Laser Sintering), SLM (Selective Laser Melting) y MJF (Multi Jet Fusion), all of which are applicable depending on the type of material or precision required.

This type of 3D printing stands out because no additional brackets required -the powder itself acts as a carrier during manufacture-, which makes it possible to produce complex shapes, internal cavities, lightweight structures and hinged assemblies in a single print.

How the PBF process works step by step

The magic of PBF 3D printing lies in its method: a process that is as precise as it is innovative. See how powder bed fusion works step by step and why it is making a difference in industrial manufacturing.

- Digital design (CAD): It all starts with the design of the part in CAD software, where every geometrical detail is defined.

- File preparation and parameters: the design is converted into an STL file and print parameters such as layer thickness, temperature or material type are set.

- Dust deposition: a thin layer of material (a few tenths of a millimetre) is spread on the printing platform.

- Selective merger: a laser (or thermal head in the case of the MJF) selectively melts the powder according to the design coordinates.

- Layered repetition: the process is repeated layer by layer until the piece is complete.

- Cooling and dust recovery: On completion, the part is allowed to cool and separated from the unfused powder, which is recycled.

- Post-processing: residues are removed, surfaces are cleaned and, if necessary, additional treatments or finishes are applied.

The results are high precision parts, with tight tolerances and mechanical properties comparable - and even superior - to those obtained by traditional methods.

Common types of PBF technologies

Depending on the material and application, there are different variants of the PBF process. The most commonly used are:

1. SLS (Selective Laser Sintering)

Use a high power laser to sinter (partially fuse) polymer particles, such as nylon (PA12 or PA11).

It is ideal for functional parts, tooling, prototypes or short production runs, and offers high strength and dimensional stability.

At Additium 3D we use this technology to produce hundreds of parts every day, optimising manufacturing times and costs.

2. SLM (Selective Laser Melting)

This variant is used with metals (stainless steel, titanium, aluminium, cobalt-chrome, etc.).

The laser completely melts the metal powder, creating pieces dense, tough and high-precision.

It is a common solution in sectors such as aeronautics, automotive or medicine.

3. MJF (Multi Jet Fusion)

Developed by HP, it uses fusion agents and thermal energy instead of lasers.

It offers more uniform finishes, high speed and accuracy, being perfect for series production and complex geometries.

At Additium 3D we also work with MJF for projects requiring high production volume y tight deadlines.

Advantages of powder bed fusion 3D printing

- Total design freedom: allows geometries impossible with other methods to be produced.

- High precision and surface quality.

- No need for brackets: the powder acts as a support during printing.

- Ideal for functional parts: not just prototypes, but final components.

- Shorter production times: parts ready in days, without moulds or tooling.

- Technical and resistant materials: from engineering plastics to high performance metals.

- Sustainability: dust reuse and waste reduction.

Real applications: how PBF is revolutionising industrial manufacturing

At Additium 3D we apply this technology on a daily basis in multiple sectors, with measurable and real results:

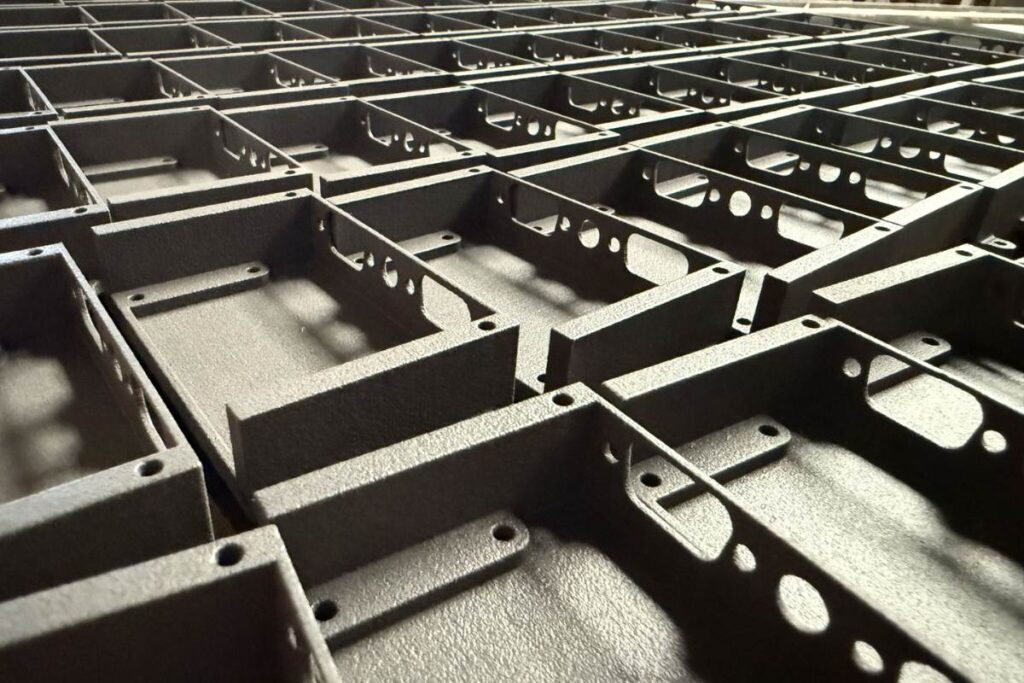

Automotive

We manufacture ducts, supports, housings, housings, tooling and functional parts with millimetre precision.

Example: a company in the industry needed a tooling that would take 3 weeks with injection moulding; with PBF we delivered it in 3 days, reducing start-up times by 70 %.

Aeronautics

We create lightweight and optimised components that reduce the overall weight of the aircraft. Thanks to design for additive manufacturing (DfAM), we eliminate joints and improve structural efficiency.

Medicine

We design and produce customised anatomical supports and parts certified for skin contact. Real example: a flexible and adaptable catheter holder with a perfect finish and high durability.

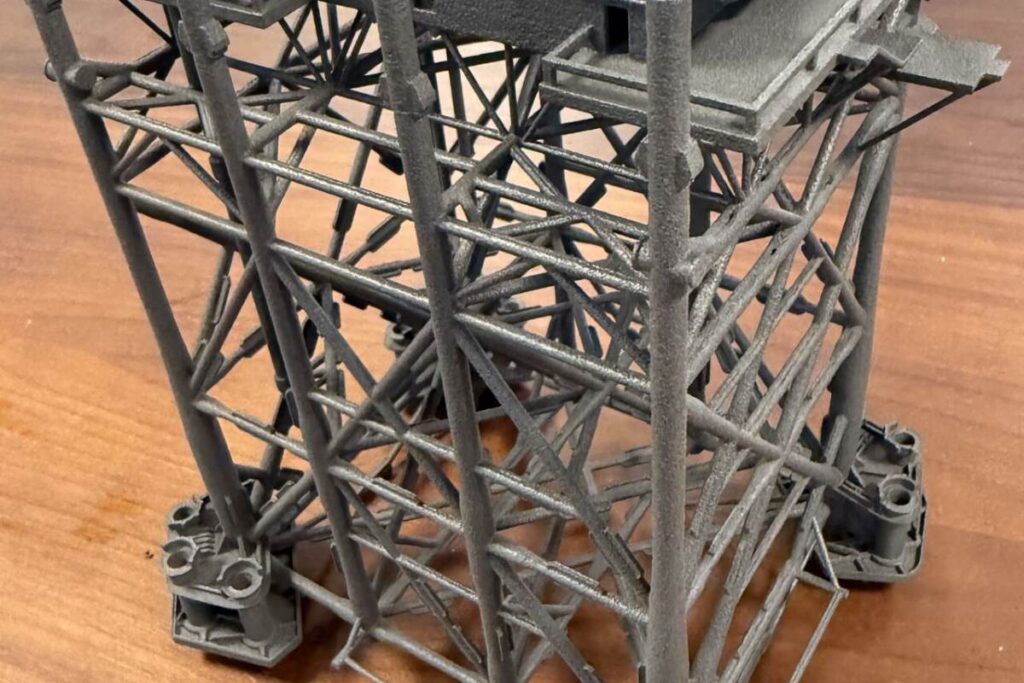

Engineering and architecture

We do accurate structural models and mock-ups, The project can be validated before work or production is carried out.

What is needed for fusion to take place?

For the PBF process to be successful, three essential elements are needed:

- Powdered material (polymer or metal) of high quality and uniform particle size.

- Controlled energy source, usually a laser or thermal melting system.

- Controlled environmentThe temperature, atmosphere and calibration of the equipment guarantee the accuracy of the process.

What kind of 3D printing technology uses a laser to fuse fine powders?

The technologies SLS y SLM are those using high power lasers for fusing fine powders of material.

In the case of SLS, the material is partially sintered (ideal for polymers), while in SLM it is completely melted (for metals).

Both offer excellent precision, superior mechanical properties and total design freedom.

What kind of printers use powder fusing technology?

Printers using PBF are equipped with:

- Temperature-controlled melting chambers.

- Uniform powder distribution systems.

- One or more lasers or thermal heads high-powered.

- Specialised software to optimise the trajectory and density of each layer.

At Additium 3D we use industrial printers from SLS and MJF technology, capable of manufacturing short and medium series with an accuracy of up to 0,1 mm, guaranteeing repeatability and consistent quality.

Additium 3D: PBF 3D printing experts for businesses

At Additium 3D we have spent years helping companies from different sectors to reduce manufacturing costs, time and complexity by means of powder bed fusion (PBF).

We don't just print parts: we offer consultancy, optimised design, prototyping and on-demand manufacture, We adapt to every need and volume.

If you want to find out how this technology can help you innovate and gain efficiency, reserve a free consultancy with our team.

The powder bed fusion (PBF) is a technology of additive manufacturing which creates three-dimensional parts from thin layers of powdered material. Each layer is selectively melted by a source of energy - usually a laser or electron beam- following the indications of a digital 3D model.

The result is a solid, resistant piece with a very high level of detail. This process makes it possible to manufacture geometries that are impossible to achieve with traditional methods, as it does not require moulds or tools.

For the powder bed fusion process to be carried out correctly, three essential elements are combined:

Suitable powder material, which can be plastic, metal or even ceramic, with a very fine and uniform granulometry.

Controlled energy source, The powder is then melted, usually by a high-precision laser or a thermal source that provides the necessary temperature to selectively melt the powder.

Calibrated and controlled environment, The temperature, humidity and atmosphere are guaranteed during the whole process, avoiding deformations or imperfections in the final piece.

The combination of these factors ensures a precise and homogeneous fusing layer by layer.

There are several technologies within the PBF family, but the most common ones used are laser as a source of energy are:

SLS (Selective Laser Sintering)used mainly with materials polymerics such as PA12, PA11 or TPU. The laser sinters the powder, i.e. partially melts it, creating a solid bond between the particles.

SLM (Selective Laser Melting) o DMLS (Direct Metal Laser Sintering)used for metals, where the laser completely melts the metal powder, making it possible to manufacture parts with mechanical properties very similar to those obtained by casting or machining.

These technologies offer high precision, freedom of design and an excellent level of finish.

Printers that work with powder bed fusion are high-end industrial equipment, designed for demanding production environments.

Among the best known are:

SLS systems for plastic materials, ideal for small series, functional prototypes and end-use parts.

MJF (Multi Jet Fusion) Systems, which combine thermal fusing with fusing and detailing agents to achieve greater precision and productivity.

SLM or DMLS equipment, specialised in metals, used in sectors such as aeronautics, automotive or advanced medicine.

At Additium 3D, we work with technology Industrial PBF, capable of producing complex, light and resistant parts, adapted to the needs of each sector.