FDM 3D Printing Technology

Fused Deposition Modelling (FDM) Service

- TPU, PET CF15, Polypropylene (PP), PLA, ABS

- The most economical for large parts

- Free delivery

Request a quote

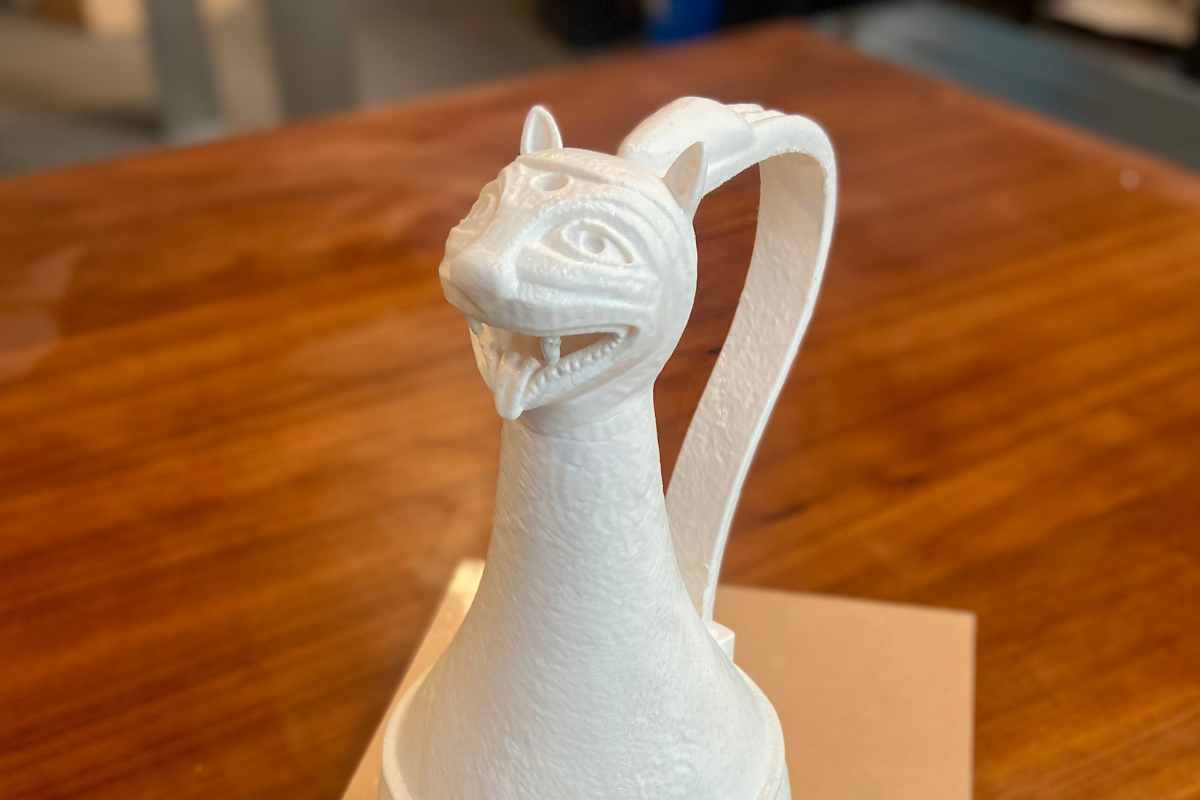

FDM 3D Printing Case Studies - Treated with Acetone

What is FDM 3D printing?

FDM printing is based on the deposition of successive layers of molten thermoplastic material, which solidifies to create the desired object. This technology is known for its versatility and is perfect for affordable projects and a wide range of applications, from prototypes to final parts. It is used in various industries.

Order in less than 3 minutes

Upload your CAD file

Upload your 3D design. If you don't have it, don't worry. At Additium3D, we will be happy to work with you to create the necessary file.

Get a quote with DFM

Within hours, you will receive a detailed design analysis and quotation with recommendations and pricing.

Manufacturing begins

Once you have reviewed and accepted the quote, we will start 3D printing your project.

You receive your order

The parts reach you in record time. And don't worry about delivery, we take care of that too, so that your parts are in your hands in just a few hours.

Why choose Additium3D 3D printing?

Tailor-made design

We serve all across Europe. And yes — you can visit us in Valencia, Spain.

Speed and efficiency

Cost reduction

Advantages and disadvantages of FDM 3D Printing

Advantages of FDM Technology:

- More economical: The initial cost is lower compared to other printing technologies such as SLS.

- Versatility of materials: Wide variety of materials available with very different and diverse properties, including plastics, composites and flexibles.

- Ease of use: Easy setup and maintenance, suitable for beginners and professionals.

- Speed: Relatively short printing times for prototyping and small-scale production.

- Personalisation: It allows the creation of highly personalised pieces.

Disadvantages of FDM Technology:

- Resolution limitations: May have limitations in accuracy and resolution of detail compared to other technologies.

- Rough surfaces: Surfaces may be rough, requiring post-processing in some applications.

- Supporting structures: Supporting structures are often needed and must be removed manually.

- Material shrinkage: There may be media shrinkage problems that affect print quality.

- Layered strength: The resistance varies according to the orientation of the printing layers.

Very high quality 3D print finishes with FDM technology

What is the best material for FDM 3D printing?

A tough and versatile thermoplastic, ideal for applications requiring durability and optical clarity.

Carbon fibre composite that improves stiffness and strength, perfect for strong, lightweight structural parts.

With low-density properties and chemical resistance, it is excellent for applications in the food and medical industry.

A biodegradable and easy-to-print material suitable for rapid prototyping projects and environmentally friendly applications.

With high impact strength and durability, it is ideal for functional and heat resistant parts.

A flexible thermoplastic elastomer, perfect for parts requiring elasticity and durability, such as casings and seals.

What can Additium3D 3D printing do for my industry?

Do you need to 3D print your personalised parts?

Upload your 3D design and receive your order with fast turnaround times. And if you don't have a CAD file created, don't worry, we'll do it for you.

Testimonials

What do they say about us?

3D printing projects carried out by Additium 3D

Replica Microscope for the production company La Factoría de los Sueños

At Additium3D, we don't just offer 3D printing, we offer complete additive manufacturing solutions. Our experience ranges from the...

Orthopaedics in 3D - We adapt a customised support for a mechanised chair.

At Additium3D, we are committed to the wellbeing of people, and one of the areas where our technology has an important role to play is in the...

Powering Innovation in Energy Storage: Power Electronics 3D mock-up for trade shows

Power Electronics, the world's leading manufacturer of solar inverters and energy storage, participated in Solar & Storage Live London,...

3D Printing in Healthcare: Design and manufacture of elastic and adaptable support for catheters

There are numerous uses for 3D printing technology in everyday life, but one of the ones that fills us with...

FAQS 3D PRINTING FDM

FDM, or Fused Deposition Modelling, printers come in a variety of models and brands. Popular examples include the Ultimaker, Prusa i3, MakerBot, and Creality Ender printers, among others. Each model may have unique features, so it is important to research and choose the one that best suits your needs.

An FDM printer works by depositing successive layers of molten thermoplastic material, such as PLA or ABS, on a platform. These layers are rapidly hardened to form the desired object. The process is repeated layer by layer until the print is complete.

The main difference of an FDM printer is the method of fused material deposition. Compared to technologies such as SLA (Stereolithography) or SLS (Selective Laser Sintering), FDM is often more affordable and versatile. However, it may have limitations in resolution and surface smoothness compared to other technologies.

The extrusion system of an FDM printer includes several key components, such as the extruder, the hotend, the extruder motor and the filament. The extruder pushes the filament into the hotend, where it melts and is deposited in layers. The extruder motor controls the speed and the amount of extruded filament.